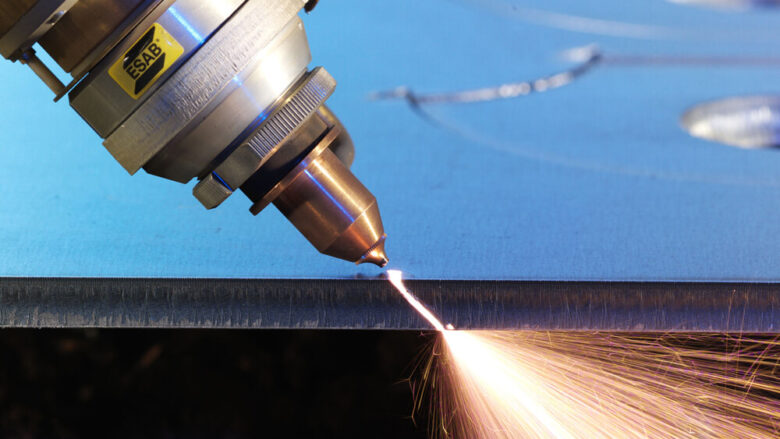

Maximize the potential of your laser cutting machine with these valuable tips for improving its performance. Learn how to achieve better results, reduce waste, and optimize your workflow for greater efficiency.

Laser cutting machines are an important tool for a variety of industries, from manufacturing to jewelry-making. However, like any other tool, they require maintenance and optimization to perform at their best. Here are some tips for improving the performance of your laser cutting machine.

Keep your machine clean and well-maintained

Dust and debris can accumulate on the lenses and mirrors of your laser cutting machine, which can affect the accuracy and power of the laser. To avoid this, make sure to clean your machine regularly, following the manufacturer’s instructions. This may involve using compressed air, a lint-free cloth, or specialized cleaning solutions. For more information, check here.

In addition to regular cleaning, make sure to perform routine maintenance on your machine, such as checking the alignment of the mirrors and lenses, inspecting the laser tube, and replacing worn parts.

Use high-quality materials

The quality of the materials you use can affect the performance of your laser cutting machine. Using low-quality materials can cause uneven cuts, burnt edges, or other issues. Make sure to use materials that are specifically designed for laser cutting, and choose high-quality materials whenever possible.

Optimize your cutting settings

The speed and power settings for your laser cutting machine can have a significant impact on the quality of your cuts. Experiment with different settings to find the optimal combination for the material you are working with. Keep in mind that different materials may require different settings, so make sure to adjust your settings accordingly.

Ensure proper ventilation and air flow

Laser cutting machines produce smoke and fumes that can be harmful if inhaled. Make sure your machine is properly ventilated to prevent the buildup of smoke and fumes in your workspace. You may need to install an exhaust system or use a fume extractor to ensure proper ventilation.

In addition to proper ventilation, make sure your machine has adequate air flow. The laser cutting process can generate heat, and the air flow helps to dissipate that heat and prevent damage to the machine.

Use proper techniques and safety equipment

To ensure optimal performance and safety, make sure to use proper cutting techniques and safety equipment when operating your laser cutting machine. This may include wearing protective eyewear, using gloves and aprons, and following proper cutting procedures.

Identifying Performance Issues

Laser cutting machines are widely used in many industries, including manufacturing, automotive, aerospace, and more. These machines are designed to precisely cut and shape various materials, such as metal, wood, plastic, and others. However, like any other industrial equipment, laser cutting machines may experience performance issues that can affect their efficiency and productivity.

Here are some common performance issues that may occur in laser cutting machines:

Inconsistent cutting quality – Laser cutting machines may produce inconsistent cutting quality due to various factors such as power, speed, and focus. This issue can be caused by a misaligned laser beam, dirty optics, or improper machine calibration.

Slow cutting speed – They may operate at a slower speed than expected, reducing productivity. This problem can be caused by a lack of power or a faulty laser resonator.

Material warping – Certain materials, such as thin metal sheets, may warp during the cutting process, resulting in uneven cuts and wasted material.

Excessive maintenance – Machines require regular maintenance to operate efficiently. However, excessive maintenance can indicate a problem with the machine’s design or components, leading to downtime and increased costs.

Safety concerns – They use high-powered lasers that can pose safety risks to operators and nearby personnel. Safety issues can occur due to improper training, lack of safety features, or machine malfunctions.

To identify performance issues in laser cutting machines, it is important to conduct regular inspections, maintenance, and calibration. It is also recommended to keep a record of the machine’s performance and identify any patterns or trends in its operation. Addressing performance issues promptly can improve machine efficiency, reduce downtime, and ultimately increase productivity.

Upgrading Components to Increase Performance

Upgrading components is an effective way to improve the overall performance of your laser-cutting machine. Here are a few tips to help you upgrade your machine and maximize its capabilities.

Upgrade the laser tube – Installing a new and more powerful laser tube can help you cut through thicker and tougher materials, allowing you to take on more challenging projects.

Replace the optics – Old or damaged optics can negatively impact your machine’s performance, resulting in inconsistent cuts and longer processing times. Replacing these components with high-quality optics will improve your machine’s precision and speed.

Upgrade the controller software – Cutting-edge controller software can help you optimize your machine’s operations and improve its overall performance. Investing in this upgrade can help you achieve cleaner cuts, faster processing times, and a higher-quality finished product.

By upgrading your machine’s components, you can take your laser-cutting capabilities to the next level and unlock new creative possibilities.

Benefits of Laser Cutting Machines

Laser cutting machines are highly advanced tools that offer numerous benefits compared to traditional cutting methods, making them an essential tool for various industries. Here are some advantages of using laser cutting machines that can improve your performance:

- High precision: Laser cutting machines use intense beams of light that can cut with high precision, making them ideal for intricate and detailed designs.

- Versatility: They can be used to cut various materials such as metals, plastics, woods, and fabrics, making them highly versatile.

- High speed: These machines are faster than traditional cutting methods, increasing productivity and efficiency.

- Low maintenance and operational costs: Once installed, laser cutting machines require less maintenance and operating costs compared to traditional cutting tools.

- Automated process: Laser cutting machines can be programmed to work continuously, reducing the need for manual labor, and increasing efficiency.

By following these tips, you can improve the performance of your laser cutting machine and achieve better results in your projects. Remember to always prioritize safety and follow the manufacturer’s instructions and guidelines for your specific machine.