Nowadays, many people have started the business of heat transfer printing. In this business, any design, pattern, or text is well-printed over any object using wax. The heat helps in melting the wax, and the design appears over the object. It is possible to copy any image on any item in whatever way you want.

There are plenty of techniques to print any design on any fabric or any object. But before you set up your store, you must have all the supplies and equipment. Before any material, you cannot print images on different objects. You have to invest money in buying all the raw materials before setting up your business.

But many people do not know about the items they need for the heat printing business. They may spend more that goes out of their budget. In the following write-up, we can help you save your money by discussing the list of items necessary for the heat press printing business.

1. Computer

You require a good-quality computer with applications to work with graphic designs. Before printing, you must create the design, pattern, or image. Your client can ask for various customizations that are possible to make using the software.

Once you complete the pattern or design,it is easy to transfer it to any object using the heat transfer technique. A computer is a necessary item that you must install in your store.

2. Heat Transfer Printing Machine

Now, you cannot transfer any design to any object if you do not have any heat transfer printing machine. It can be an expensive investment, but it is impossible to do your job without this equipment.

You can get plenty of options from different brands, and it can be difficult for you to choose the best machine. Take your time to read all the features and buy the one that fits your requirements. You can also click here to buy one of the best heat transfer or pressing machines.

What differs these from regular ones are:

- large heating pad in size of 15×15″

- Digital Control Board

- Adjustable Pressure Knob

3. Ink

Different ink types are commonly used for printing designs on different objects by using heat press printing machines to get the desired finish on any object. There are plenty of options that you can choose from. But the affordable and commonly available ink in inkjet. You can access it from any place and use it on your project.

But if you are looking for better options, then you can go for the pigment and sublimation ones. When you want fade resistance, it is better to use the pigment one, but when you want indulged printing, you must go with the sublimation ink.

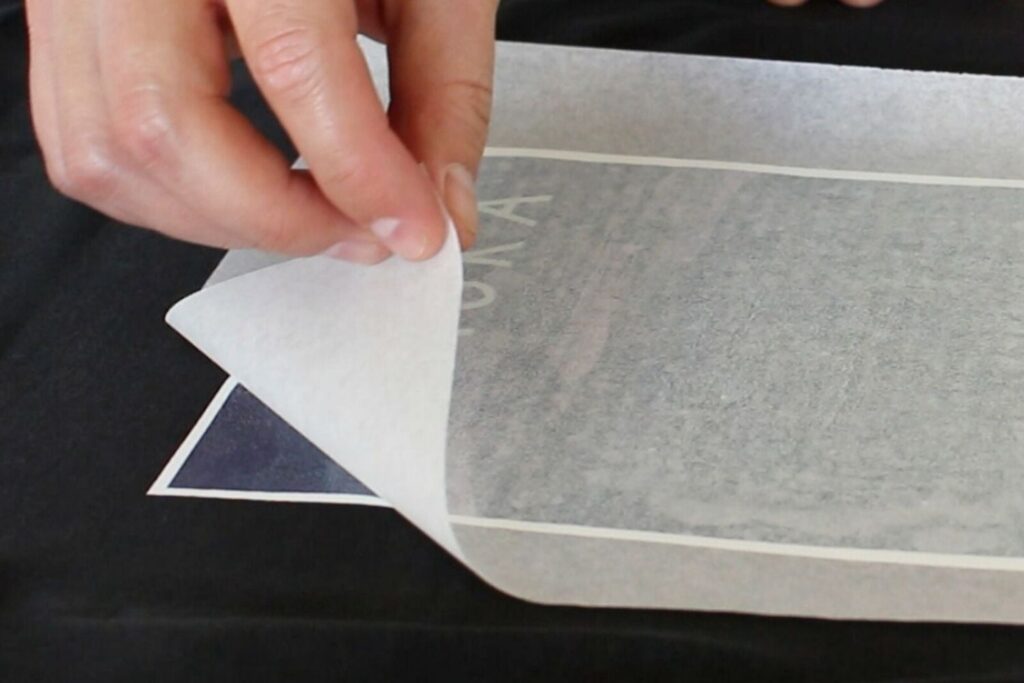

4. Paper

You have to invest in a special paper for heat transferring the image you want on any object or fabric. This paper is coated with wax or polymer. When the heat is applied to the design over the wax sheet, it gets attached to the fabric’s fiber.

The commonly available size of the sheet is 13 x 19 inches for better design. You can place any design within these measurements and print them on any object.

5. Cutter

When you print the design on the paper, you need to cut a piece of that paper to extract the design. Instead of wasting the whole sheet, you can cut a piece and use the left sheet for printing other items.

You need a vinyl cutter to do this job accurately. It is better to avoid using scissors or another cutter. It may not cut perfectly, and your entire sheet will get wasted. Through a cutter, you can cut the sheet quickly and save time.

6. Press

You have to buy a heating press to be installed in the machine. You can get the equipment in different shapes as well as sizes. It is better to buy the ones that are quite essential for the business. If you want a heat press for printing designs on T-shirts or other fabrics, then you can prefer swing flatbed or clamshell heat presses.

But if you need to print anything on rounded objects, then you must use heat presses available in a cylinder shape. The rounder objects can be mugs, bottles, etc.

7. Pads

Before beginning your business and getting projects from your clients, you have to learn the technique of printing anything on any object using the heat transfer technique. Initially, you need pads that you must place at the bottom of the press.

It helps you a lot while learning the procedure of heat transfer. In this way, you can avoid several mistakes and keep yourself safe. These pads are commonly available in silicon rubber material.

8. Tape

You require a tape for keeping the paper in its place. You may be wondering whether it can bear the heat. It is a special heat-resistant tape, and you can use it to stick the paper in one place. Even if you are an expert in printing, you must be careful while doing your job.

This way, there are fewer chances of spoiling the sheet and getting an incorrect print on any object. If you need to avoid rework, then you must use the tape for safety.

9. Substrates

It is a product that requires decoration. You can get orders of different substrates like T-shirts, mugs, bags, etc. In better words, it is like a canvas where you have to print the design. One needs something on which one can print any design, quote, or pattern. Even if you are practicing using the heat transfer machine, you have to try on different objects.

Final Thoughts

While starting your heat transfer printing business, it is necessary to invest your money in various supplies and equipment. Before you print for your clients, ensure that you practice enough to do your job with perfection.

The investment cost depends on your requirements. You can spend more money on high-end projects with massive printing goals. All equipment is available from different brands with different qualities. You can invest your money as per your requirements.